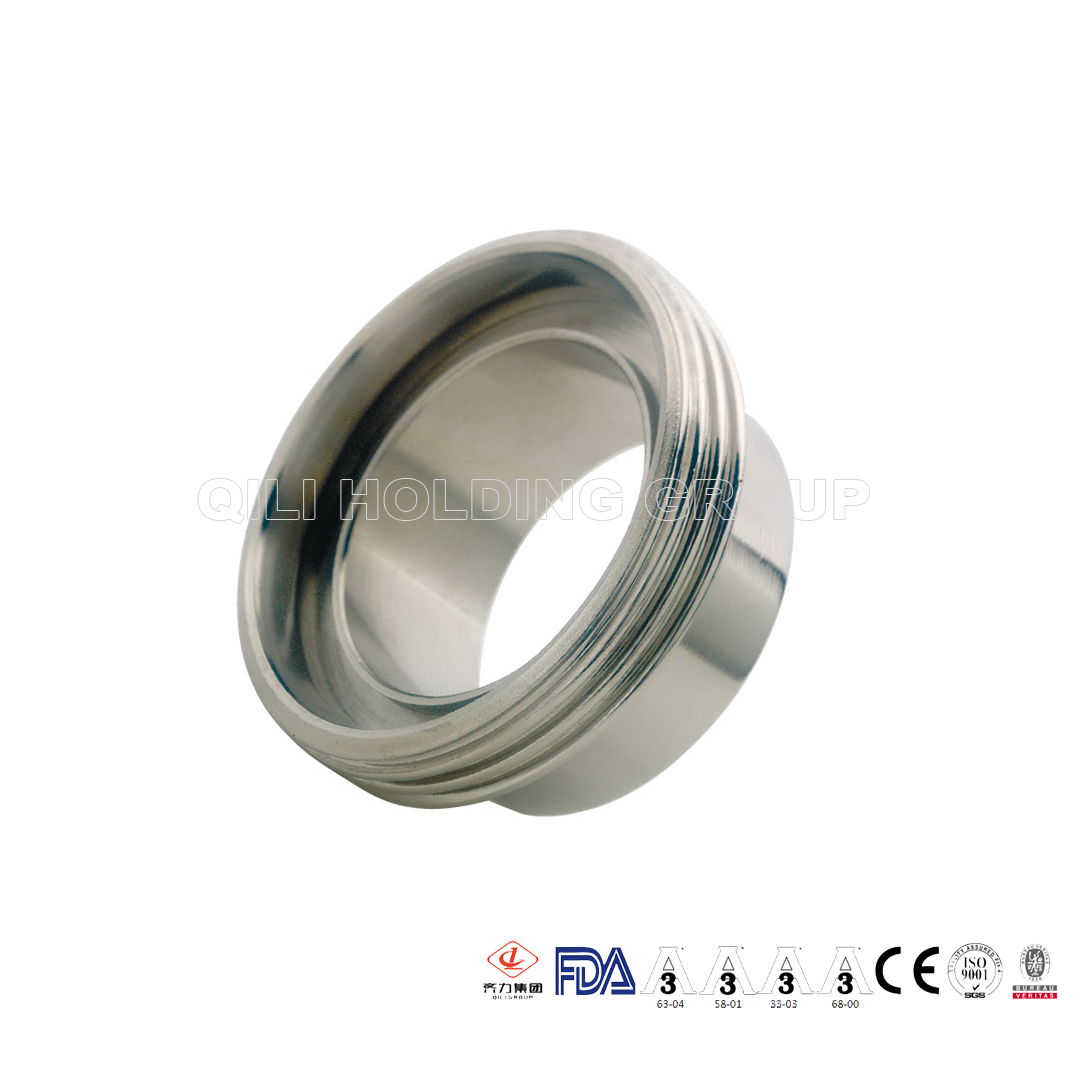

Sanitary Stainless Steel Check Valve Clamped End

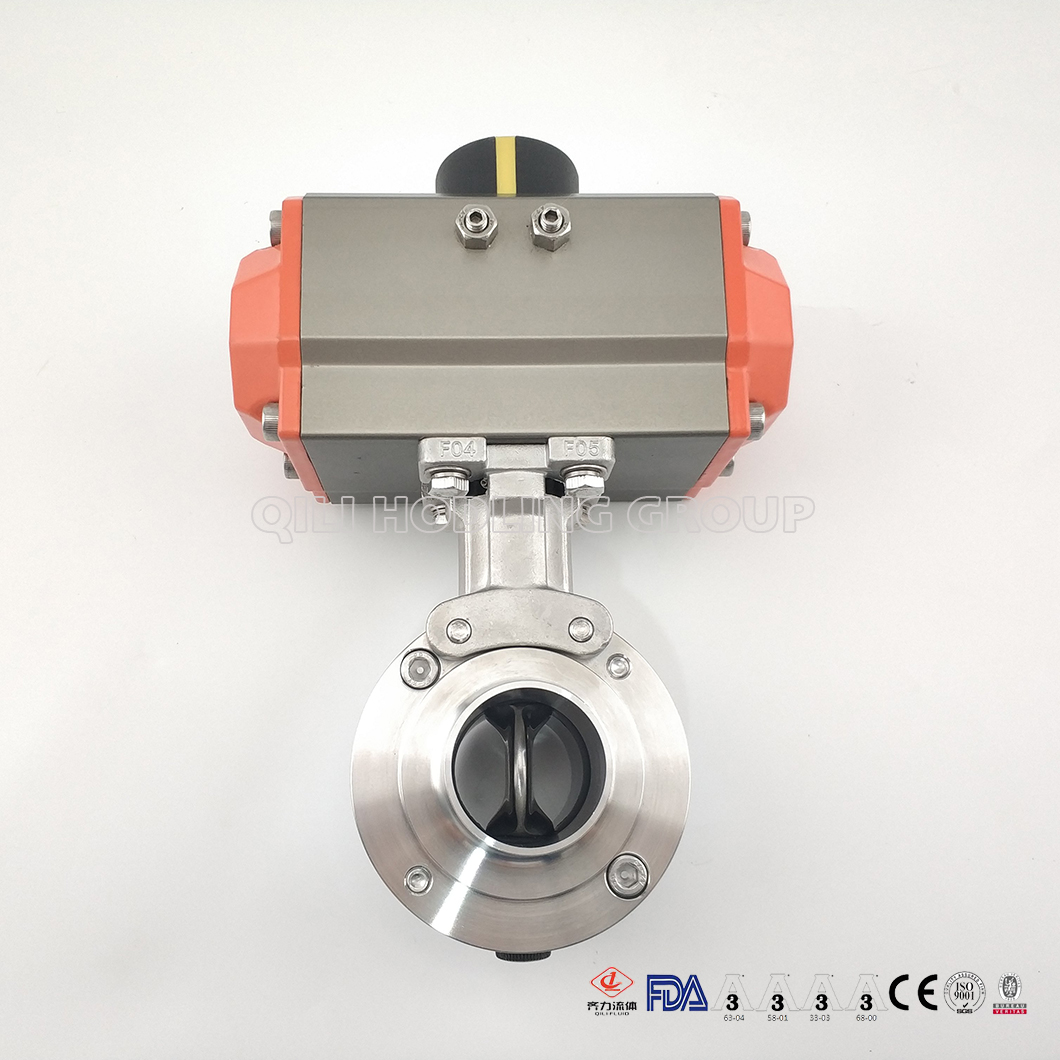

Check Valves are widely used for both sanitary and industrial applications to prevent backflow of product.

Ball Check Valves are designed to allow full product flow during processing. Ball Check Valves are commonly used with liquid products. Air Blow Check Valves are designed to evacuate lines of product or CIP solutions. Once the product flow stops, the ball rolls back to the seat at the inlet preventing back flow.

Offered with Sanitary Tri-Clamp® or Sanitary Butt Weld ends. Other connections are available upon request

- Material:

- SS304,SS316L

- Standard:

- DIN, 3A, SMS, ISO/IDF, BS/RJT

- Working Temperature:

- -10 to 140℃

- Connection ways:

- Welded, clamped, threaded

- Size:

- DN25-DN100,1-4"

- Sales Models:

- Retail and wholesale

- Surface Treatment:

- inner( Ra ≥0.4-0.8μm),outer(0.8-1.6μm)

- Pressure Value:

- 0-10bar

- MOQ:

- 1pcs

- Seal Material:

- EPDM, FPM,silicone,VMQ,

- Transport Package:

- cartons

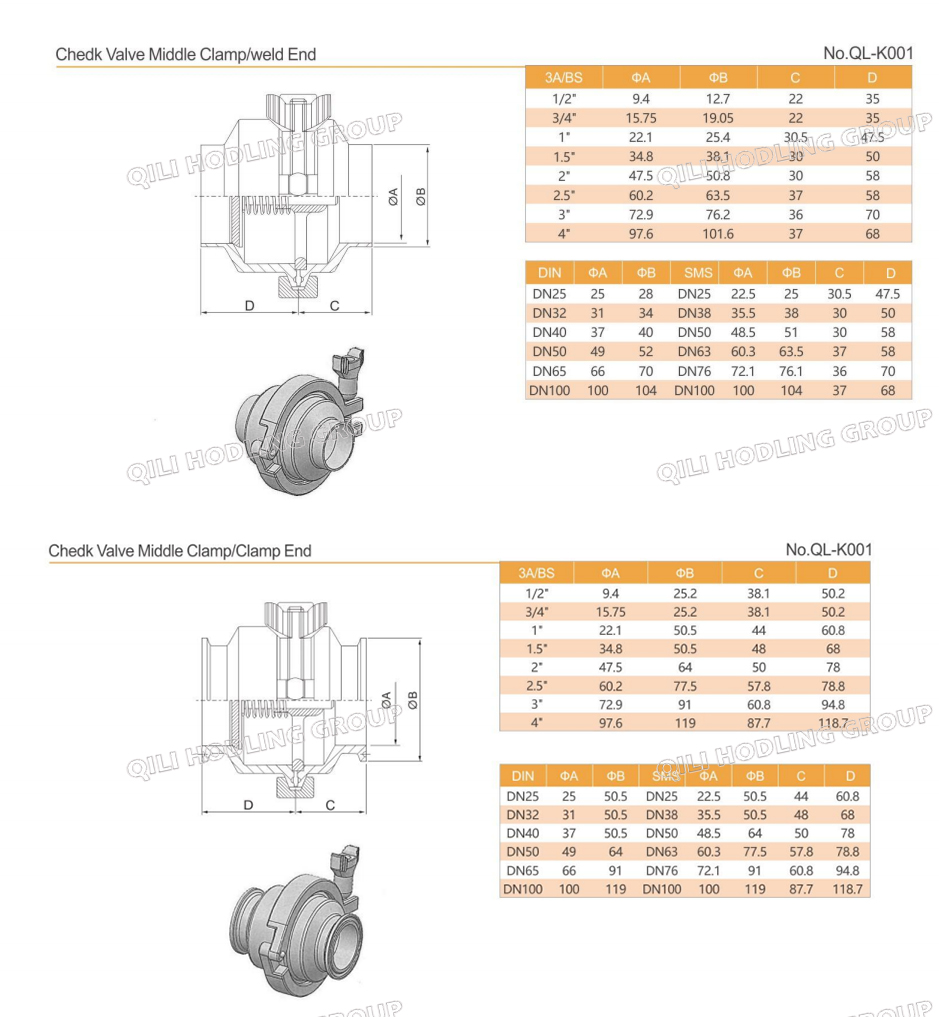

Drawings

Details

| Description | Sanitary Stainless Steel Check Valve Clamped End |

| Body Material | Stainless Steel 304; Stainless Steel 316L (Forged, 1.4301/1.4404) |

| Actuator Material | Stainless Steel 304 |

| Seal Material | EPDM, VMQ(Silicone), NBR(Nitrile), VITON, all meet FDA standard |

| Temperature Range | 15°F to 200°F(-9.4°C to 93°C) EPDM |

| Max. Pressure | 10bar (140psi) DN25 ~ 100; 8bar (120psi) DN125 ~ 150 |

| Finishing | Ra 16 ~ 32µin (0.4 ~ 0.8µm) electropolish available |

| Port Size | DN25-DN100,1-4" |

| Connection | Tri-clamp ferrule; Threaded; Welded |

| Connection Standard | 3A , SMS , ASME BPE, ISO, DIN, BS |

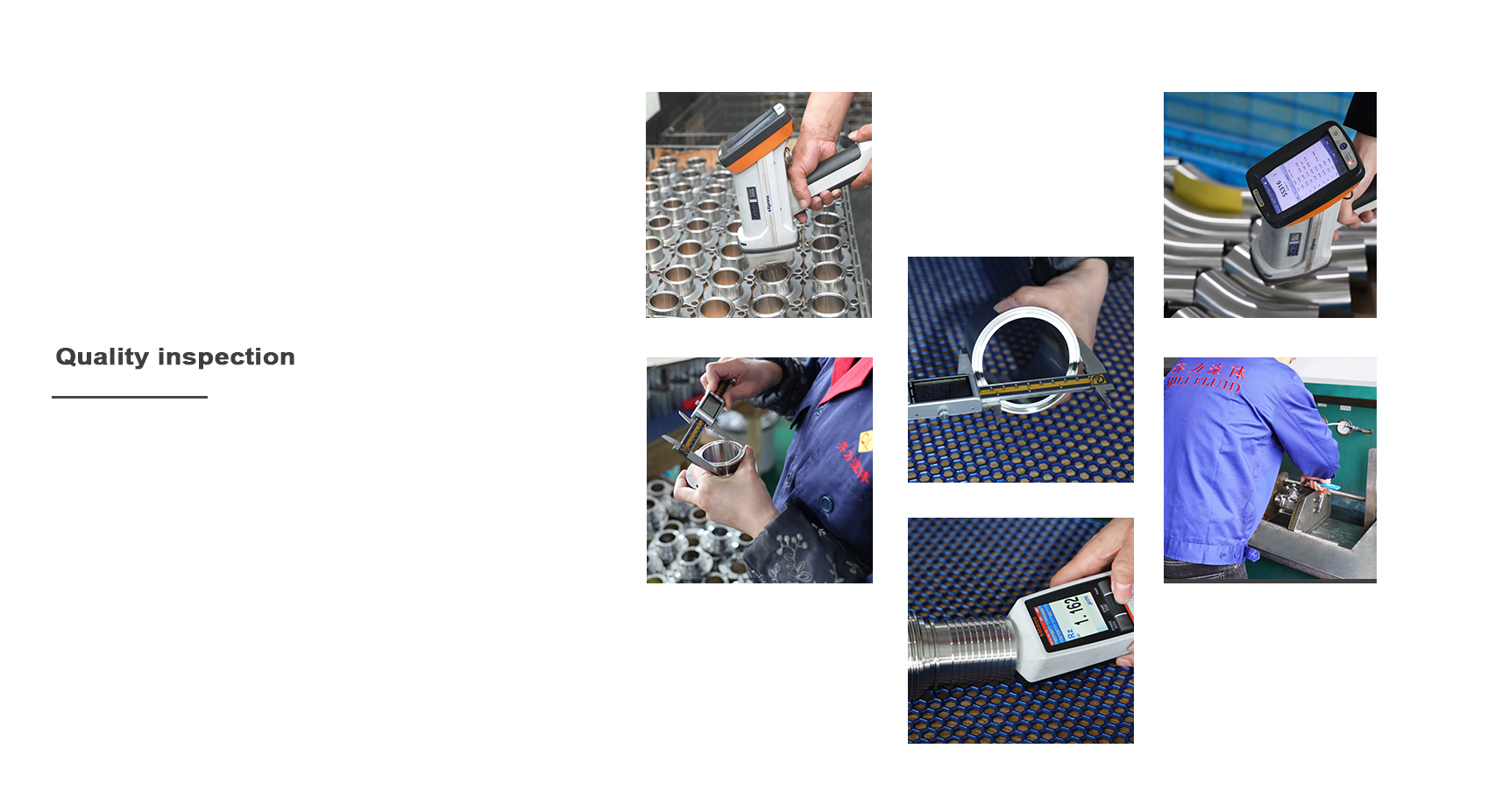

| Features | 100% hydraulic tested / 100% inspected |

| Specifications | Can see our products catalogues |

| Application | Food process, Milk process, Beer brewage, Bio-pharmacy, etc. |

| Packaging | Carton packaging. Wooden case packaging. |