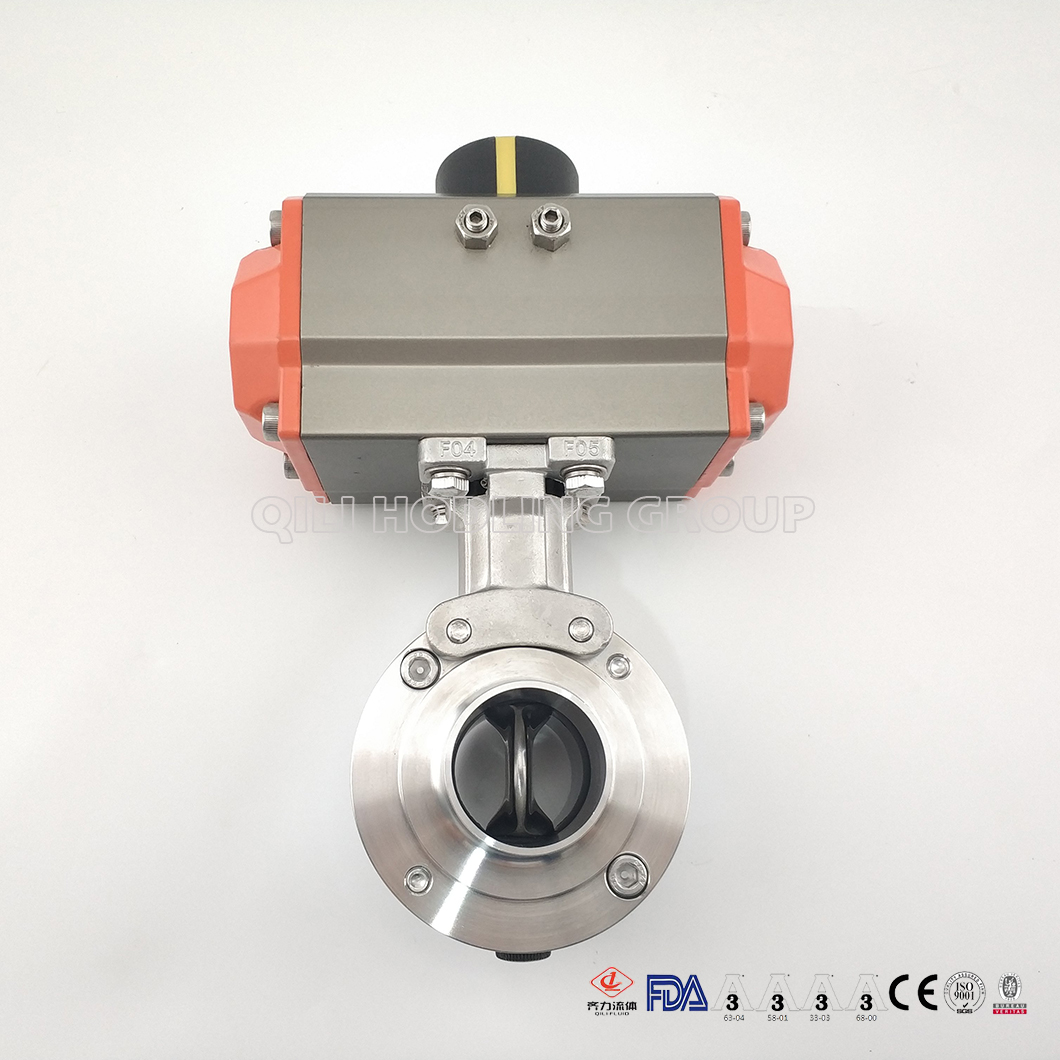

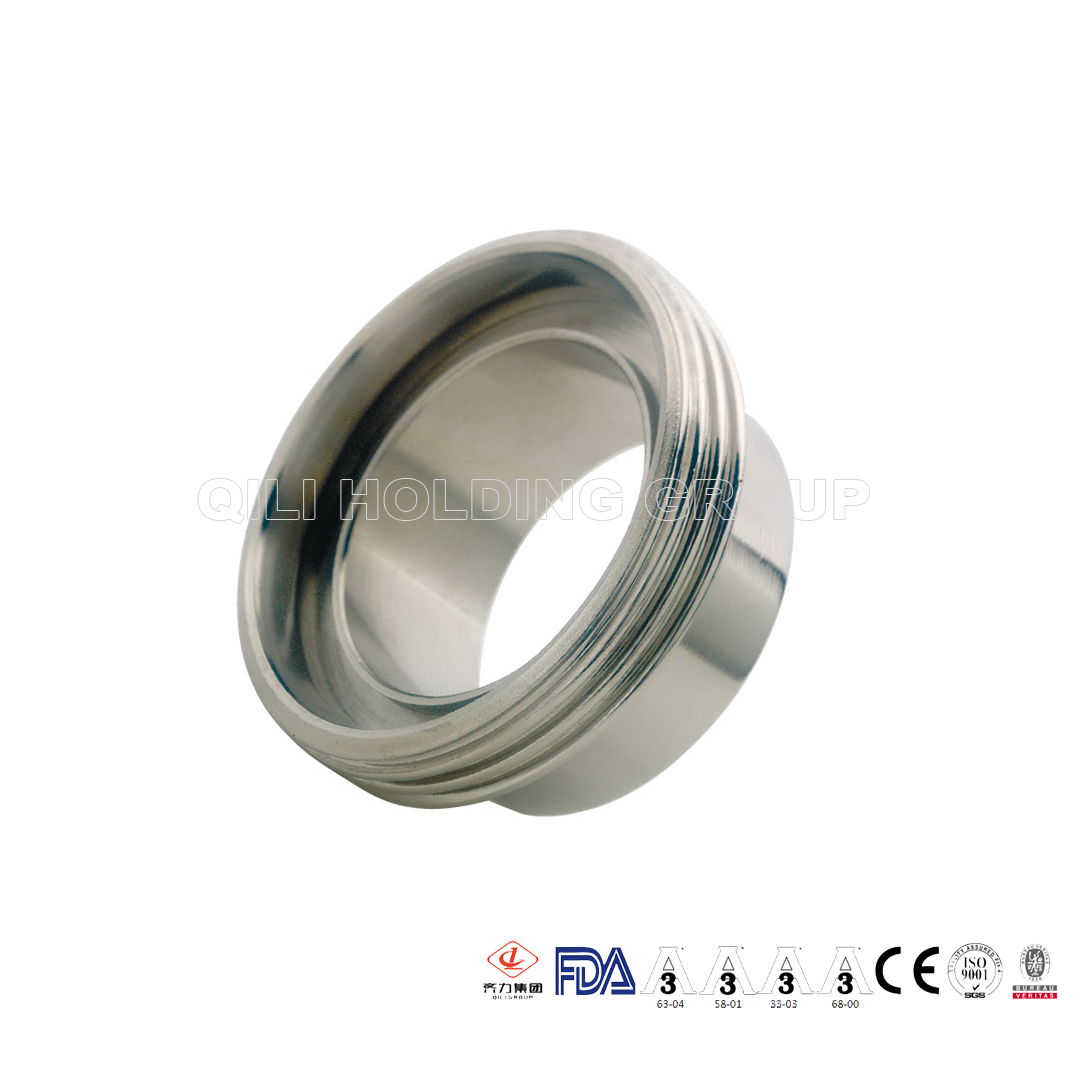

High Quality Manual Food Grade Full Bore Encapsulate PTFE Ball Valves

The valve is designed as an encapsulated valve, which solve the problem of liquid retention valve cavity.the valve is in biopharmaceutical , beverage processing, brewing, refinery, cosmetics and chemical industry, valve rod sealing design,Butterfly spring compensation design,encapsulated PTFE design, It has the advantage of long life ,small torque,no retention

- Material:

- SS304 /SS316L

- Standard:

- 3A,SMS,ISO,RJT,DIN,IDF

- Working Temperature:

- -20 to 150℃

- Connection ways:

- welde,clamp, thread

- Size:

- 1/2" -6", DN15-DN100

- Sales Models:

- wholesale or retail

- Valve Seal:

- encapsulated

- Surface Treatment:

- Ra 16~32µin (0.4 ~ 0.8µm) electropolish available

- Pressure Value:

- 10 bar(140psi) DN25~100; 8 bar(120psi)DN125~150

- MOQ:

- 1PC

- Seal Material:

- EPDM,VMQ(Silicone),NBR(Nitrile),VITON,all meet FDA standard

- Transport Package:

- cartons

Details

- 1.Name:China Manual 3PC sanitary Tri clamp ball valves with full bore ball valves

- 2.Size:Dn15-150 and 1"-6"

- 3.Connection way:Tri clamp,weld,male, flange

- 4.Work Pressure:Mid-Pressure (2.5mpa< Pn <6.4mpa)

- 5.Working Temperature:-20 ~ 135° C

- 6.Material of Seal Surface:Soft Sealed

- 7.Medium:Beer, Dairy, Beverage, Pharmacy, Cosmetics

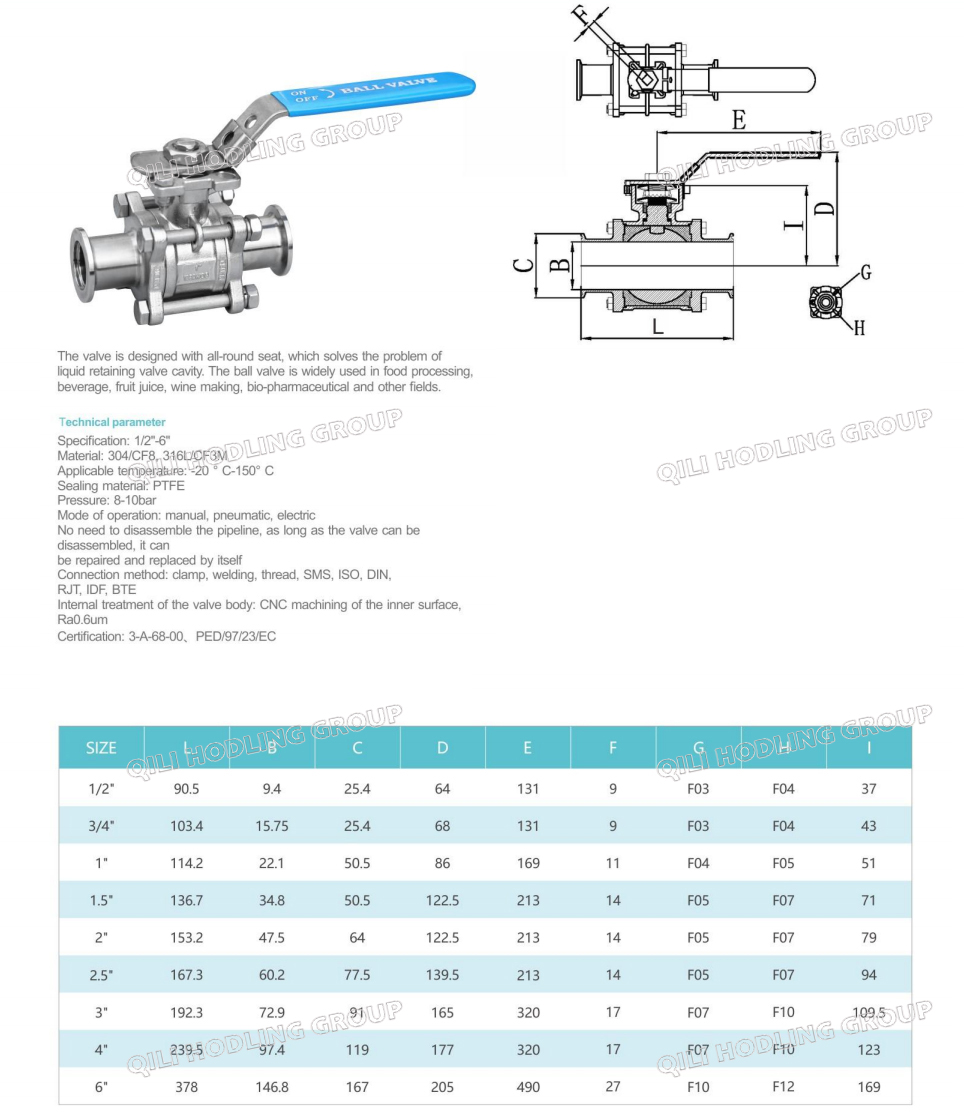

Drawings

Advantages

In 2019,Qili was fully upgrade all ball valve.the upgraded design more suitable GMP、ASM、 EBPE、EHEDG and 3A of high purity technology requirement,especially for dead space handle processing <1D to <3D requirement. The valve is designed as an encapsulated valve, which solve the problem of liquid retention valve cavity.the valve is in biopharmaceutical , beverage processing, brewing, refinery, cosmetics and chemical industry, valve rod sealing design,Butterfly spring compensation design,encapsulated PTFE design, It has the advantage of long life ,small torque,no retention